Spitting and poor fan pattern are obvious indicators that it’s time to dial in your paint sprayer. However, even when you’ve achieved the perfect coverage, it doesn’t mean you have the most efficient setup. If you’re looking for more speed, less overspray, or less wear and tear on your machine, it might be time to study up on tips. Who better to help us navigate the array of tip choices, than spray equipment authority, Graco.

Spray Tip Sizes

Using the right tip for the application is the first step to ensure a successful and efficient paint job,” says Tyler Sterner*, Global Product Marketing Manager at Graco.

He recommends that pro painters start by understanding different tip sizes.

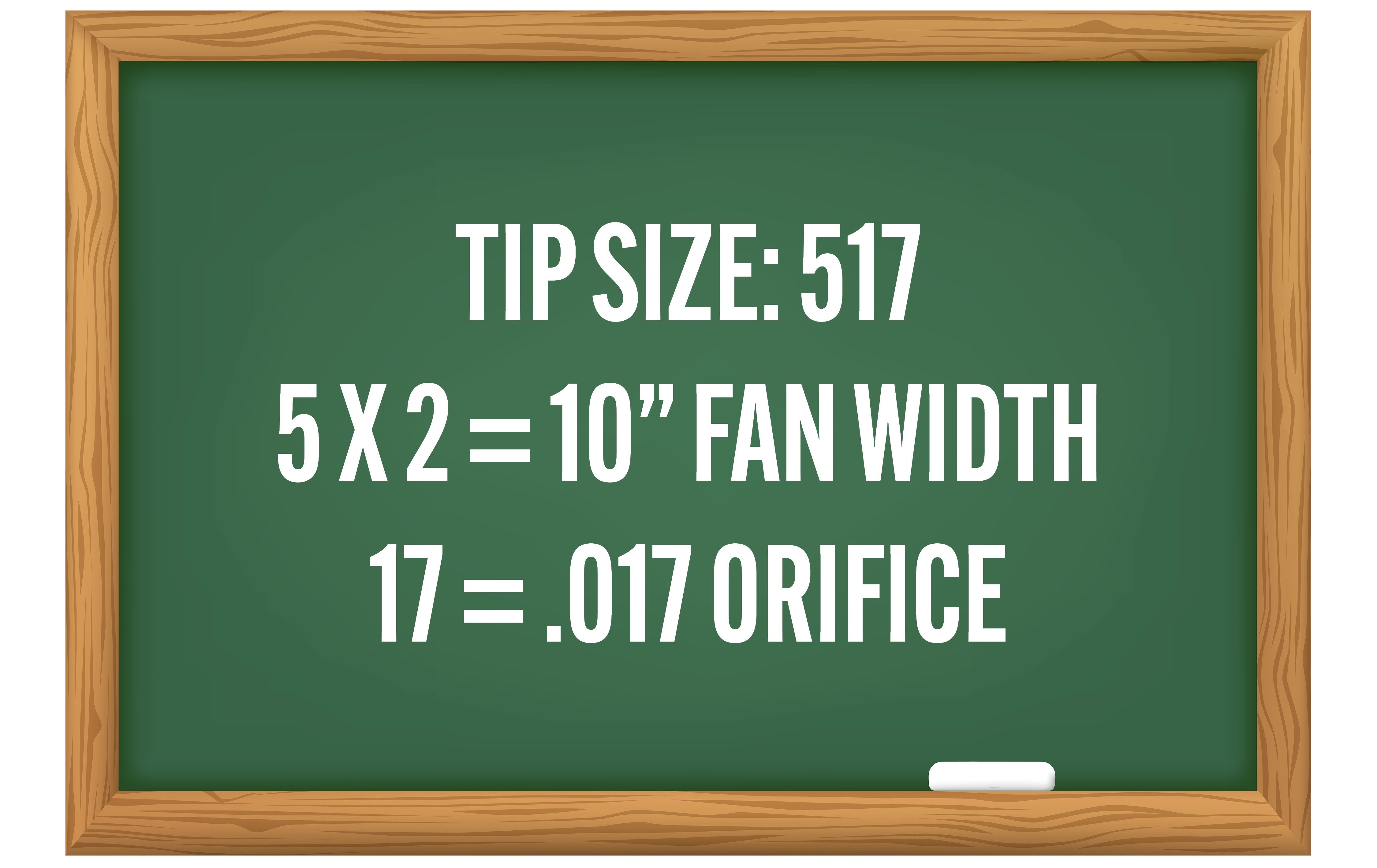

The spray tip has three to four printed numbers. The first digit, or the first two digits in the case of four total digits, represents the fan width. The second two digits denote orifice size, which determines the amount of paint that flows through the spray tip.

Fan Width – Multiply the first number by two to get your fan width in inches.

Paint Flow – The second two numbers are measured in thousandths of an inch.

Tip choice depends on the coating, application and experience of the operator. Refer to the back of the can or TDS for recommendations appropriate for that coating.

Of course, with thicker coatings, you need a larger orifice, but many paint products generally indicate a 515 or 517,” says Sterner. “The RAC X LP 517 comes standard on all Graco professional airless units.”

Overall, these suggestions are general and don’t account for every specific application; just like there is a diverse range of application possibilities, there’s an array of tip options to meet each need.

Speed

First, consider the size of the surface.

If you’re spraying a tilt-up wall on the exterior of a commercial building, the 517 will work, but it isn’t going to give you the speed you want.”

For this application, Sterner suggests considering a Wide RAC Low Pressure 1227 which features a 24-inch fan pattern and a wider orifice to increase flow. “It makes the job significantly faster.”

Second, keep in mind the operator. The larger orifice allows for higher flow and thus faster spraying. However, it doesn’t only allow faster spraying, it requires it.

If you have someone less experienced on the gun moving too slowly, it can cause runs and sags,” says Sterner. “A smaller orifice will be more forgiving to a newer operator.”

Finally, spray tips don’t improve with age. If you believe performance has improved after the tip has had many gallons sprayed, it’s more likely that the orifice has gotten larger over time resulting in higher flow and a thicker millage on the wall.

I’ve had a lot of painters tell me that they are happier with the speed after they’ve sprayed many gallons of paint through the tip. Most of these contractors didn’t realize they could purchase tips with larger orifice sizes, enabling them to apply paint much faster.”

Sterner recommends bumping up an orifice size or two so you can get your desired production speed right out of the box.

Overspray

Smaller jobs like cabinet doors or spindles have different requirements. Here, the fan width should match up as closely as possible to the surface size. This not only reduces overspray, but it also decreases wasted paint.

If you are using a 310 on spindles, you’re likely to get four to five inches of overspray. You can catch the overspray with cardboard, but you’re wasting a lot of coating. An FF LP108 would be a much better option,” says Sterner.

Wear and Tear

Paint is basically liquid sandpaper running through the spray system. Higher pressure creates higher speed and velocity, which means the parts are eroding faster,” says Sterner.

To extend the lifespan, use RAC X Low-Pressure SwitchTips, the latest breakthrough in Graco’s portfolio of offerings. These tips allow you to set the pressure on your machine to about half of what regular tips would require while still maintaining an even, consistent fan pattern.

This has a lot of advantages including cutting your overspray and making everything in your spray system last longer.”

Sterner notes that you should always test your tips and pressure settings on a piece of cardboard before you begin your project.

Sterner adds that some contractors assume low-pressure tips are only suitable for finishing applications.

RAC X Low-Pressure SwitchTips are designed for every architectural paint project, from small-scale jobs to large commercial applications. No matter the scope, we have a low-pressure spray tip that meets your production needs.”

With the right paint and application methods, you can grow customer satisfaction, referrals and your business. Be sure to keep up with all of Graco’s latest products and techniques by visiting this page for helpful tips.

Great article Emily. I have been with the company for 22 years, and this article will help me better engage customers looking for info on sprayers and tips.

As with most spraying demos the efficiency & even coating is always achieved better with spray pole AND swivel to keep perpendicular to sprayed surface. Less fatigue & better results. I think a demo on this for painters would be advantageous

Great information. Very helpful!